It began with a feasibility study on the subject of "Fish-box Recycling" in 2001.

In 2002, CreaCycle GmbH and the Fraunhofer Institute for Process Engineering and Packaging (IVV) in Freising agreed on a cooperation with the aim of "Recycling of Valuable Materials with the CreaSolv® Technology (selective extraction - IVV) using CreaSolv® Formulations (CreaCycle) and focusing on Plastics". For this purpose CreaCycle registers the CreaSolv® Trademark and establishes it in the plastics recycling market in order to differentiate from competition and to better identify the service and product offerings of the partner companies.

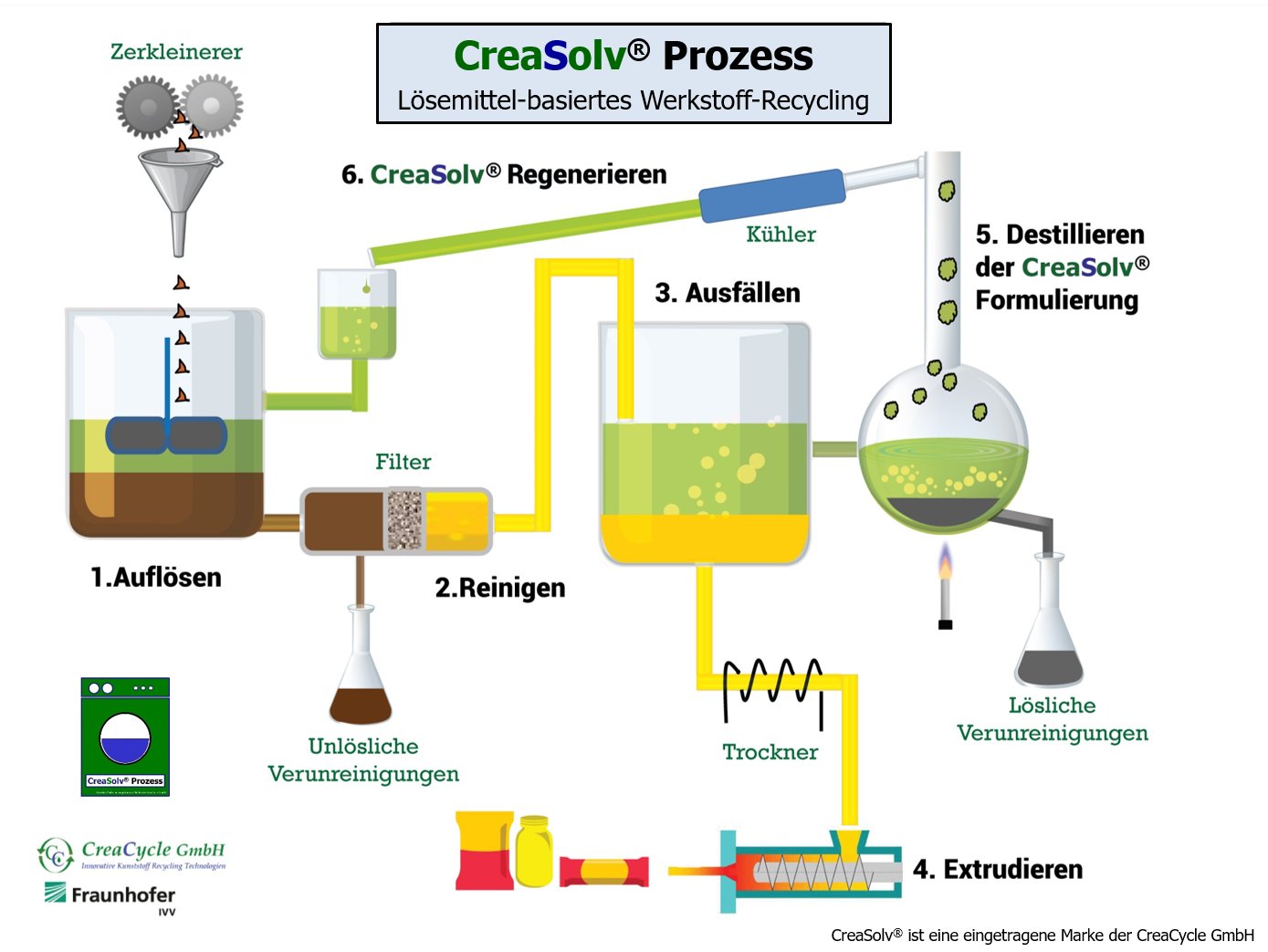

On this common basis CreaCycle and Fraunhofer Institute IVV developed together the CreaSolv® Process, based on standard process technology (patented by Fraunhofer Institute). It is called Solvent-based Purification (synonym: Dissolution Recycling).

Proprietary CreaSolv® Formulations with the lowest risk potential possible for user and environment (ideally not to be classified according to GHS criteria) dissolve selectively the thermoplastic polymers. This reduces besides the hazard also the cost for the equipment. After the cleaning from impurities the desired polymer precipitates when a special CreaSolv® Precipitation agent is added.

The volume of solvents used is very small in relation to the processed plastic (<1%), because the CreaSolv® Formulation is run in a closed-circuit.

- 1. Dissolution After sorting by polymer type the plastic waste is shredded and dissolved in a vessel with a tailored CreaSolv® Formulation. The target polymer and certain impurities dissolve.

- 2. Cleaning Insoluble impurities are separated to produce a clear solution. The impurities will be waste-handled or can be recycled if they contain valuable substances.

- 3. Precipitation By changing the solubility property of the solution only the polymer drops out and can be regained.

- 4. Extrusion The dried recycled polymer is extruded into new polymer granulates with similar properties like the virgin material, thus allowing it to be used in the original application.

- 5. Distillation (Purification) The solution is collected and distilled in order to recycle the CreaSolv® Formulation. The remaining insoluble impurities are collected to be waste-handled or recycled if they contain valuable substances.

- 6. Regeneration The recycled CreaSolv® Formulation is again used for the dissolution of plastic waste.

Download CreaSolv® Process Infographic

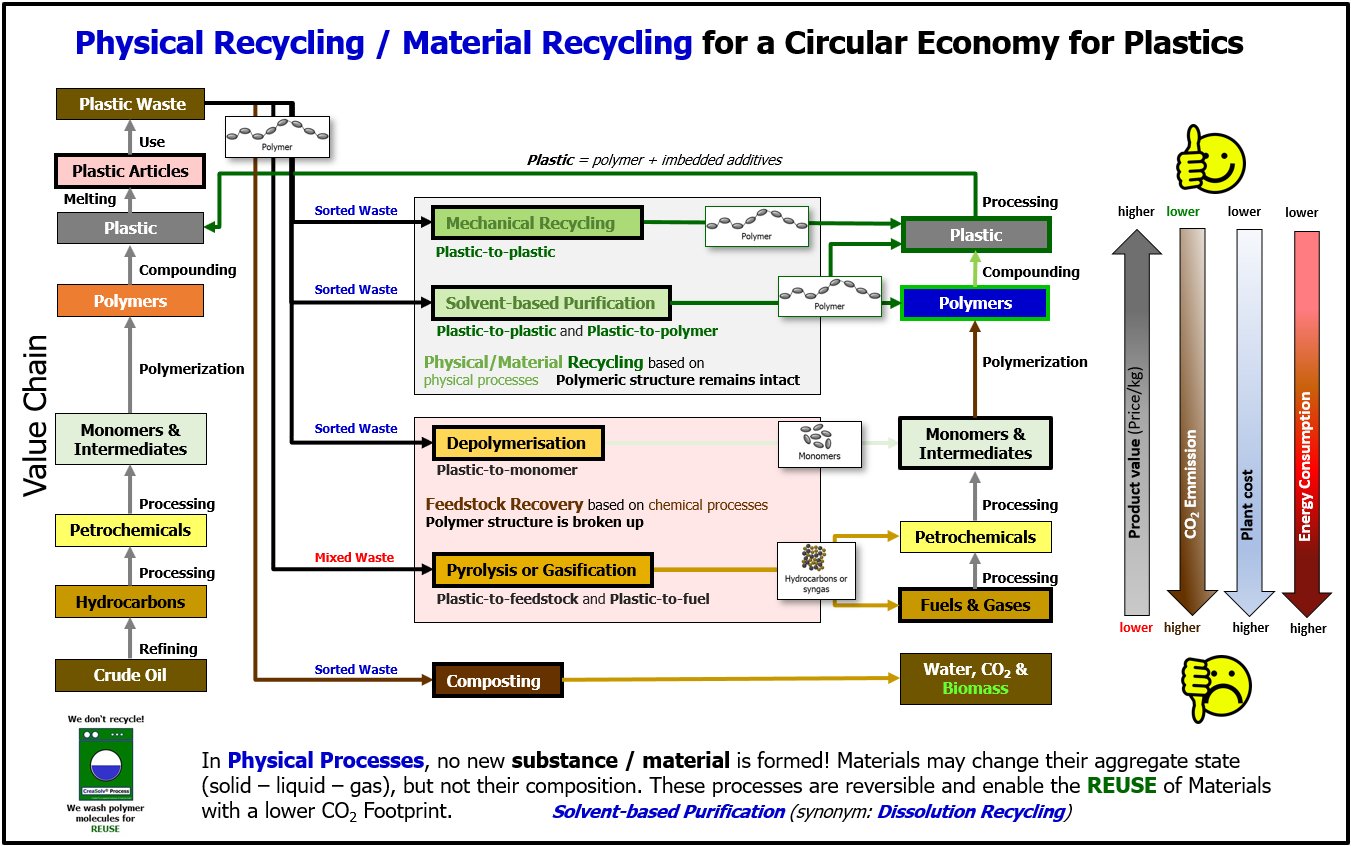

Material Recycling / Physical Recycling

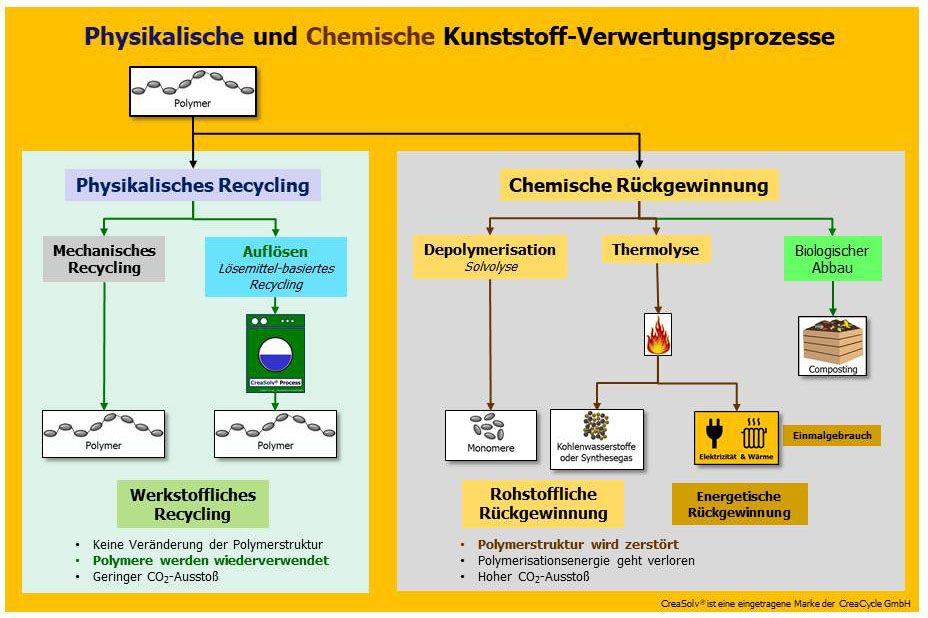

The dissolution of plastic is a physical process, because the substance/material only changes its physical state from solid to liquid, and this can also be reversed again. It is for this reason why the CreaSolv® Process is classified as Material Recycling. It works like a washing machine on a molecular level.

The CreaSolv® Process does not fall into the class „Chemical Recycling“, but into Physical Recycling, because the chemical structure of the polymer chains remains unchanged, so that they can be reused. Chemical processes always produce new substances.

The CreaSolv® Process does not fall into the class „Chemical Recycling“, but into Physical Recycling, because the chemical structure of the polymer chains remains unchanged, so that they can be reused. Chemical processes always produce new substances.

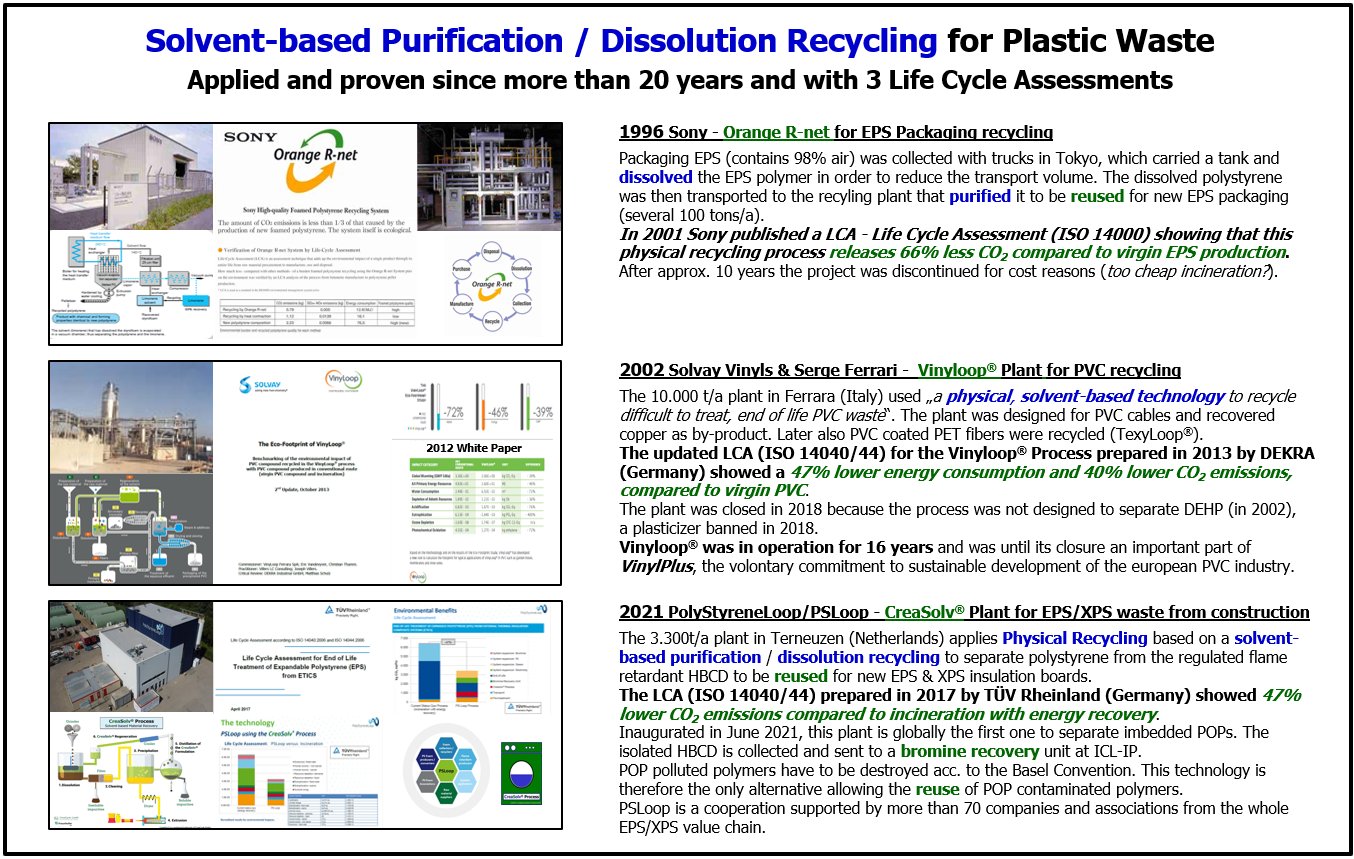

Sony's Orange R-net process for recycling packaging EPS worked with solvent-based purification and was already used in Japan in the 1990s.

Solvay's Vinyloop® plant for recycling PVC cables had a capacity of 10,000 tons per year and operated in Italy from 2002 to 2018. Then it had to be closed because this plant was not designed to separate the now banned plasticizer DEHP.

It is therefore incomprehensible that there is still no industry standard or norm in which this solvent-based purification technology occurs, although there are several life cycle assessments for it that prove its usefulness.

In ISO 15270 "Guideline for the Recovery and Recycling of Plastic Waste" or EN 17615 "Plastics - Environmental Aspects - Vocabulary" one looks for it in vain and in the "EU Taxonomy Report" it is even wrongly classified as chemical recycling. -> see CreaSolv® Position paper

CreaSolv® Process: Applications and Polymers

Over the years, the CreaSolv® process has been successfully tested and modified for various plastics, applications and problems (a selection follows):

Multilayer Packaging

Separation of brominated flame retardants

Separation of banned plasticizers

Fiber reinforced composites

Metal/Plastic composites

Further application examples can be found in the menu (upper left) under Projects, sorted by application.

Life Cycle Assessments

As early as 2001, Sony published a life cycle assessment of the Orange R-net process for packaging EPS with 66% lower CO2 emissions than the production of virgin EPS. The commercial Vinyloop® process for PVC cables showed 47% lower energy consumption and 40% lower CO2 emissions compared to virgin production, according to a 2013 DEKRA life cycle assessment.

The life cycle assessments of the CreaSolv® Process for different polymers and applications also convince with a low CO2 footprint, similar to that of mechanical recycling.

To date, the following CreaSolv® Life cycle assessments are available:

Separation of brominated flame retardants.

- EPS – Construct – TÜV Rheinland: PS Loop

- EPS – Construct – ifeu Institut: PS Loop

- EPS – Construct – ifeu Institut: PS Loop

- ABS, HIPS, PC – WEEE - UNIVAN: NONTOX

- ABS, HIPS - WEEE - WRAP-Study: WRAP

- PE, PP – ELV – UNIVAN: NONTOX

Multilayer Packaging

- PLA – Fraunhofer Umsicht: SustRecPLA

- PE (60%) - Fraunhofer Umsicht: MultiCycle

- PE (75%) - Fraunhofer Umsicht: MultiCycle

- PET – Fraunhofer Umsicht: Multicycle

Fiber Reinforced Plastics (ELV)

- PP (55%) – Fraunhofer Umsicht -> MultiCycle

- PA (50%) – Fraunhofer Umsicht -> MultiCycle

More information can be found in the project pages.

Recycling of EPS Insulation waste, contaminated with persistent organic pollutants (HBCD).

Recycling of EPS Insulation waste, contaminated with persistent organic pollutants (HBCD).

Please click on picture to start video.

For more information please read about the PS Loop - Link

Recycling of Metal-Plastic Compounds and Hybrid Materials.

Recycling of Metal-Plastic Compounds and Hybrid Materials.

Please click on picture to start video.

For more information please check the Forcycle Project - Link